MEI have ensured world-class quality in design, equipment and operations through vertical integration – Designing, Validating, Casting, Machining, Assembling & Testing are all done by MEI. Each of our plants has separate quality control units to monitor the manufacturing quality of our products. Our facilities ensure that we are able to provide best-in-class products to the automobile industry across worldwide.

MACHINING

Vertical integration is key to our philosophy. As well as our own cast housing we produce all critical components in house at our Ambattur site. Special purpose horizontal machining centers ensure that housing machining is controlled in-house at our assembly facilities at Maraimalai Nagar and Mahindra City. All the 4 production plants are in and around Chennai, Tamil Nadu State. MEI manufactures Slack Adjusters, Clutch Boosters & Air Disc Brake Callipers to fulfill domestic & Export business requirements.

ASSEMBLY

Our seven station no fault forward assembly lines allow Full flexibility and can accommodate single piece build of 600 different part number in Slack Adjusters alone. Also well as use of Poka-Yoke systems our staffs are trained in Six Sigma for continuous improvement. All parts go through end of line test routines to ensure 100% reliability.

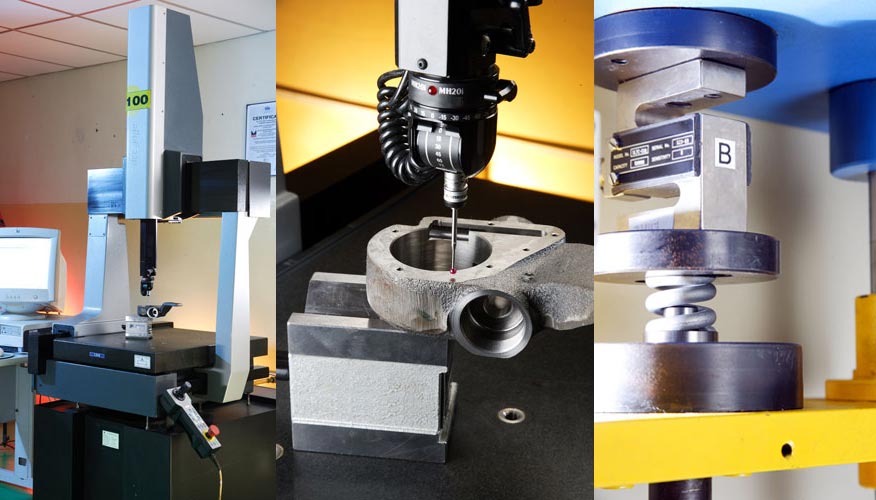

QUALITY

The quality and reliability of MEI products is ensured thru the quality excellence systems. Commencing with DFMEA and PFMEA all existing and new products are continuously evaluated for their quality and reliability robustness. All MEI plants are certified to comply with ISO/IATF16949 -2016, ISO14001 -2015, OHSAS 18001 – 2007 and are periodically audited for compliances by the quality team. All vendors are continuously audited for compliance to laid down standards and also for due upgradation of quality systems. The quality department is equipped with a most modern metallurgical laboratory, material testing equipment, CMM, etc for conducting various special and regular tests.